Unlock improved manufacturing processes and performance

The problem many organisation face is that MRO supplies are often purchased through multiple budgets and included in numerous processes. This often leads to a misunderstanding of the importance of the category and poor procurement practices. Indeed, MRO purchases often fall into the tail spend of many organisations and are provided by multiple vendors with no coherent strategy to deal with the complexity.

Our white paper demonstrates how changing procurement practices and making use of either ERP systems, CMMS, stores software or vendors to track, manage and control inventory can streamline processes. This will ensure key MRO items are on hand as soon as they’re needed. Centralising the acquisition of inventory and tracking maintenance repair and operating supplies, simplifies the process and improves organization.

We explore the following key elements:

- What is the definition of MRO (Maintenance Repair and Operation).

- Describe how good MRO procurement practices can deliver cost savings.

- Discuss supply chain resilience in the new world of disrupted supply chains

- Show how good MRO procurement can unlock improved manufacturing processes and performance.

- Using good MRO procurement practice to release working capital back into the business.

- How to work with the supply chain to improve stock control and warehousing practices.

- What is an MRO Consolidator?

- What are the advantages and disadvantages of outsourcing the procurement of MRO through the supply base.

Download the full white paper today.

Download the full white paper today

Please enter your email address to download this file.

"That’s been one of my mantras – focus and simplicity. Simple can be harder than complex: You have to work hard to get your thinking clean to make it simple. But it’s worth it in the end because once you get there you can move mountains."

What is MRO (Maintenance Repair and Operation)?

Maintenance Repair and Operation (Hereafter referred to as MRO) should not be confused with Maintenance Repair and Overhaul, which is a common practice in the airline industry to maintain fleets of aircraft.

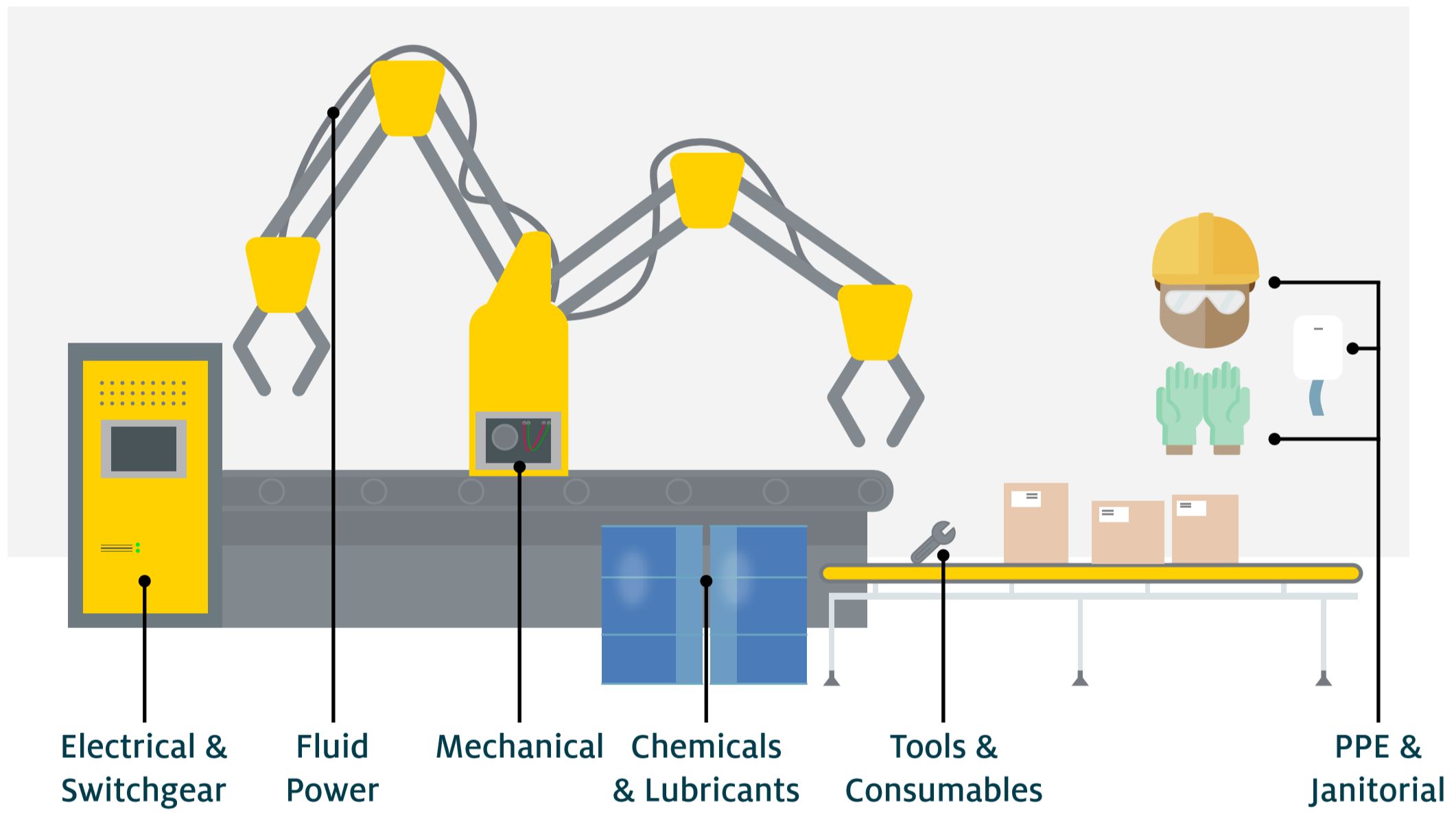

MRO in this context is the procurement of spare parts and equipment, such as pumps and valves, consumables such as cleaning supplies, plant upkeep supplies such as lubricants, and activities completed to restore or maintain the functioning of needed equipment. Anything used in the manufacturing of, but not employed in, a final product may be considered MRO.

Cost Saving Opportunities

Effective MRO procurement can deliver a wide range of cost saving opportunities. These typically fall within six main areas:

- Supplier Consolidation

- Stock control

- Improved Supplier Service

- OEE improvements and reduced engineering down time

- Supplier Innovation

- E-procurement, Industrial Internet of Things (IIoT) and Process streamlining

Our white paper explores each of these areas in more detail, providing detailed examples of how cost savings can be achieved.

Download the full white paper today and start discovering the cost saving opportunities available within effective procurement of MRO.

Key Product Categories for MRO

Why it is important to have sound MRO procurement processes

The MRO value chain closely mimics a typical Material Resource Planning (MRP) process. However, the outputs are slightly different in that they track supplier performance, stock management and maintenance requirements. The value chain outputs can be used to reduce costs (Item price and process costs), release cash (reduced stock holdings and elimination of obsolete parts) as well as drive operational performance through efficient maintenance practices.

There are 3 core components that drive the MRO value chain, which is fundamental to establishing effective MRO procurement processes:

- IT infrastructure

- Operations

- Operational support activities

Our white paper explores these core components, offering guidance and examples of how you can implement them in your own business. Download the full white paper today.